STÄRKE Finishes

Aluminium powder coating services specialising in perfectly coating long profile lengths

A quick tour of our powder coating facility

How do we powdercoat?

Powder coating begins by pre-treating the aluminium in a chromate-free solution to clean the metal of any impurities. When the metal is clean, it gets loaded onto the powder coating line which is moving at a constant speed. The aluminium lengths are charged with a current, and the dry powder is charged with the opposite current as it exits the nozzle. This attracts the powder to the metal ensuring an even coat over the whole profile. The metal then passes through the oven where the powder is melted together around the aluminium to form a durable skin in almost any colour.

Powder coating has many benefits over other coating methods:

Durability: Highly resistant to corrosion, flaking, and scratching with a flexible, durable finish.

Variety: Customizable finishes and colours, offering versatility and range.

Environmental Safety: Free of toxic chemicals and solvents, with minimal waste and safer disposal. Safety gear recommended for handling.

Quality: Smooth, drip-free finish with no need for sanding or refinishing.

Maintenance: Low-maintenance with resistance to corrosion and damage; easy cleaning with soapy water.

Contact

We’d love to hear from you

Got a question or enquiry? Send it through!

Roy Boquiron

roy@starke.co.nz

022 373 2602

Roy Boquiron

Powder Coat Division Manager

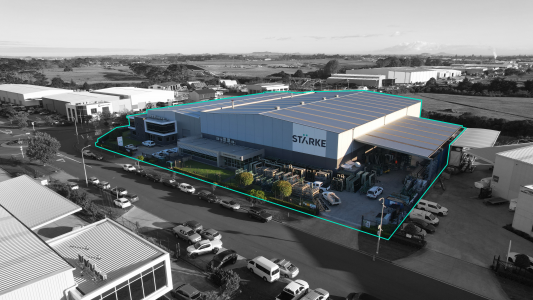

Our Location

Powder Coat Facility

4 Wilco Place

Wiri Auckland